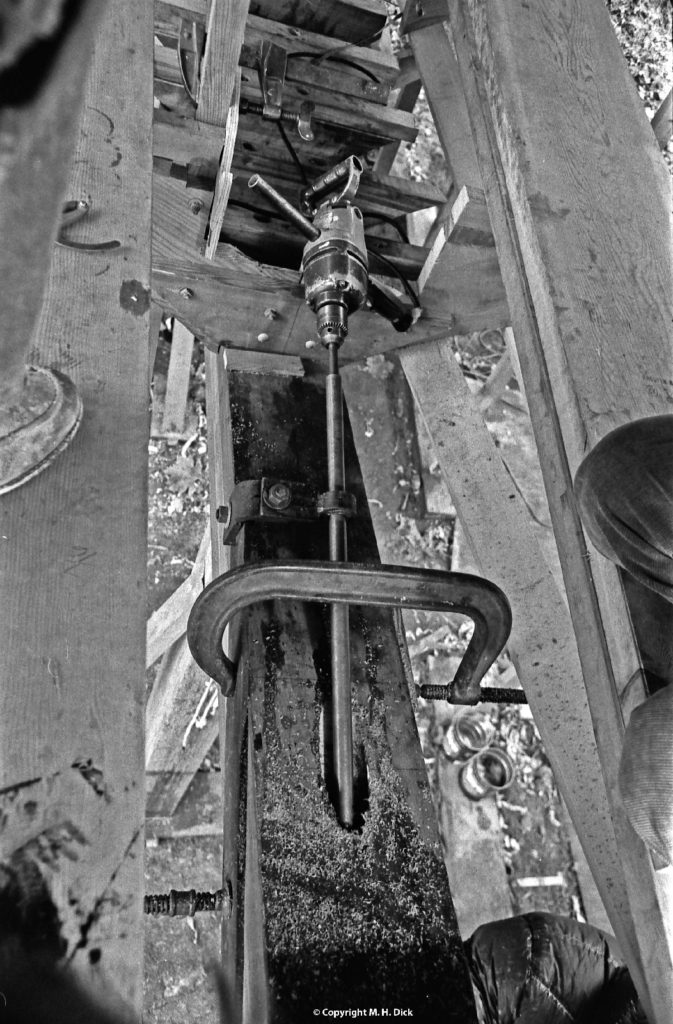

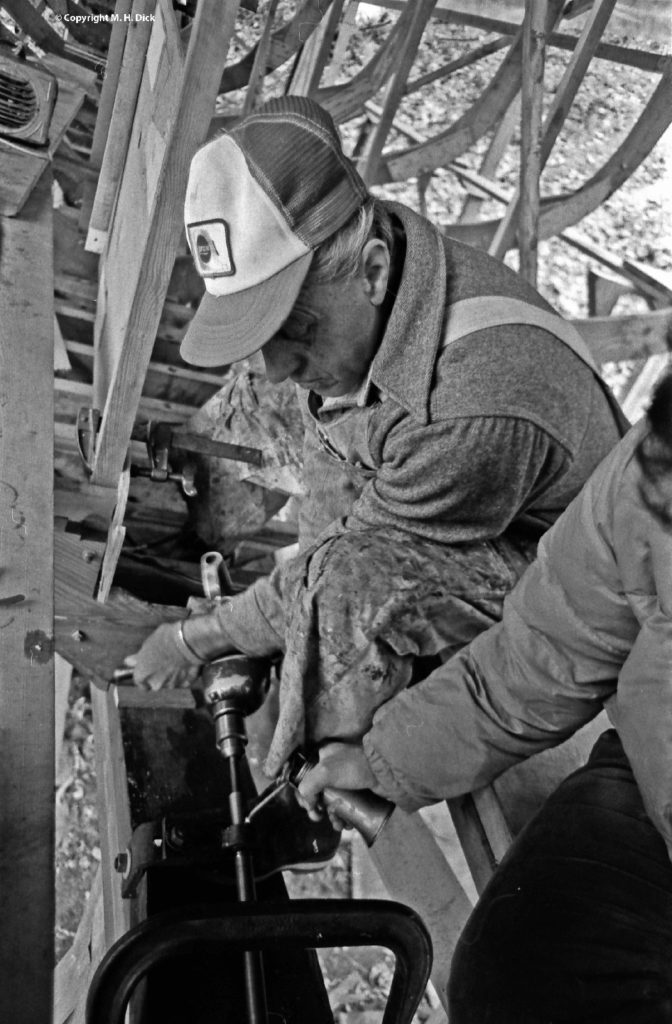

This section illustrates the shaft-boring jig used to bore long propeller- and rudder-shaft holes. To my knowledge, this tool was not commercially produced, and shops had to have it specially built in a welding or machine shop. This tool takes some of the guesswork out of drilling shaft holes. A relatively narrow guide hole is drilled first by sight and estimation. The jig’s cutting rod is then inserted through the guide hole and held in place in the correct position by a bearing clamped at each end of the guide hole. An adjustable bit on the cutting rod allows holes of various diameters to be bored. The beauty of the shaft-boring jig is that it allows an accurate shaft hole to be drilled even if the guide hole emerges somewhat off center. The Bates shop had a shaft-boring jig, which Trumbly would let students borrow for off-campus work, but he would lend it only to current students, over whom he had some leverage to ensure the jig was returned. Some of the photos from other sections are repeated here because they also deal with the shaft-boring jig.

<Prev. Next>