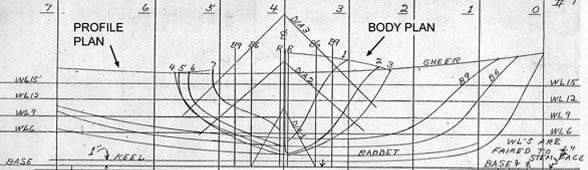

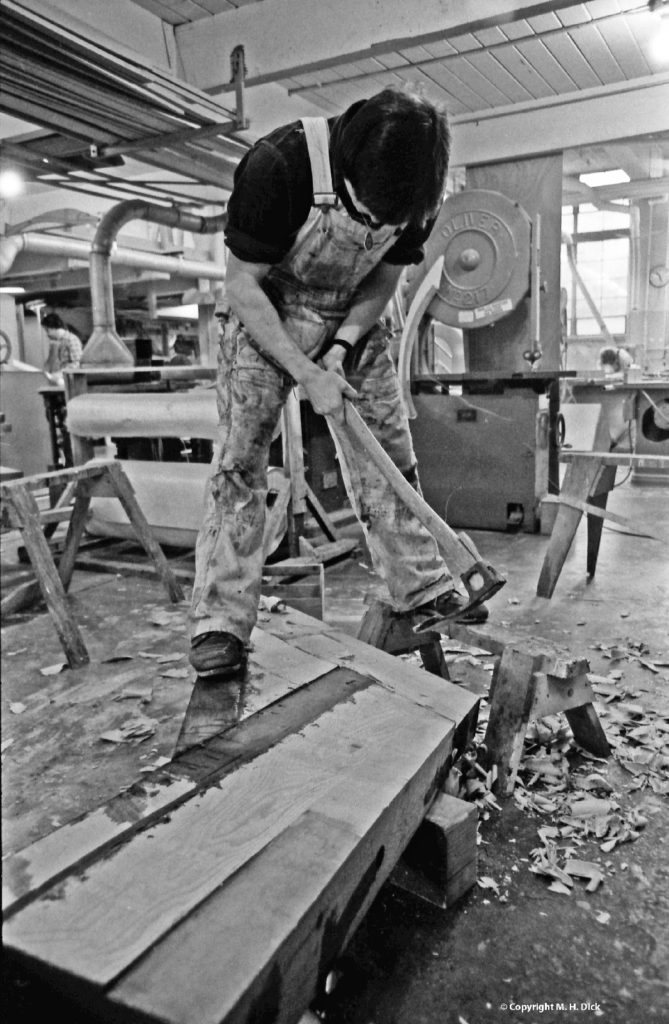

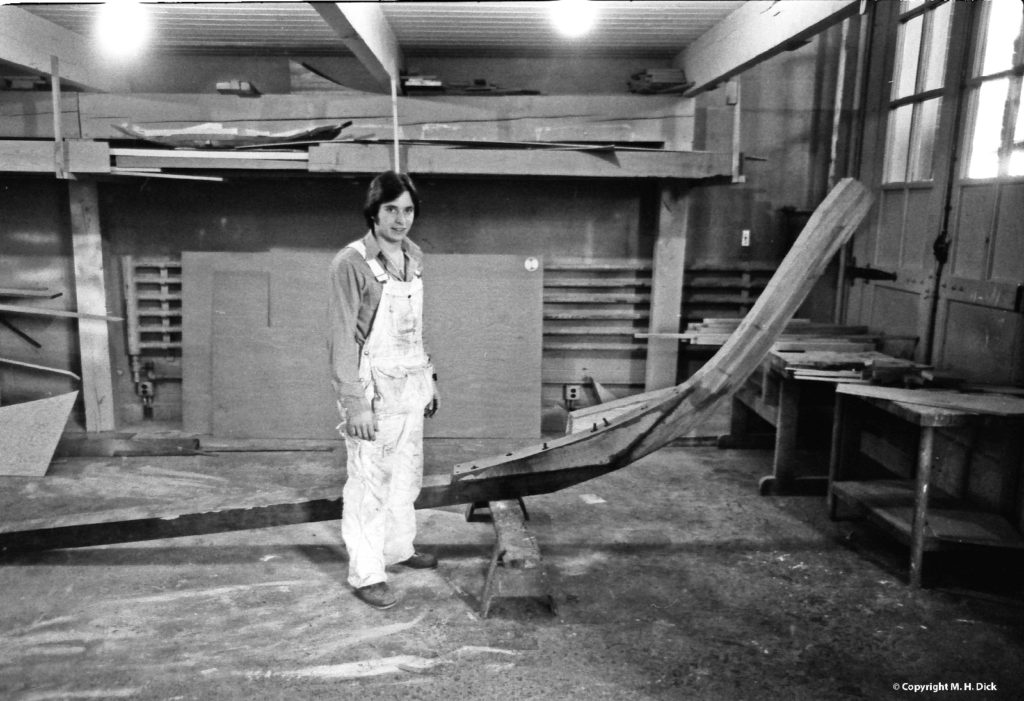

This section shows the construction of the skeleton of a 19′, bent-frame, carvel-planked sailboat being built by student Brian Saucier in the Bates shop. When I arrived at Bates in September 1977, the skeleton of the Trumbly 38 had been completed and was being planked. Brian’s boat was thus the only chance I and students who started with me had to see the initial stages of setting up a bent-frame boat. Trumbly wryly called Brian’s boat “the biggest little boat in the world,” for a boat of this size would usually have sawn frames and be built upside down on a strongback. Brian constructed this boat upright with bent frames, a mode of construction that would normally be used for much larger boats.

Unfortunately, Brian graduated from the boatbuilding program soon after completing the skeleton and was unable to finish the vessel. When I visited the new Bates boatbuilding shop on the South Campus around 2003, I was surprised to see the skeleton for Brian’s boat in the shop, pretty much as I’d last seen it. Brian had donated it to the boatbuilding program for an interested student to finish, 25 years after he started it. I will include a lot of photographs here, for the construction details will be of interest to boatbuilders.

<Prev. Next>